Cardboard Box Manufacturing Services

Packaging Design

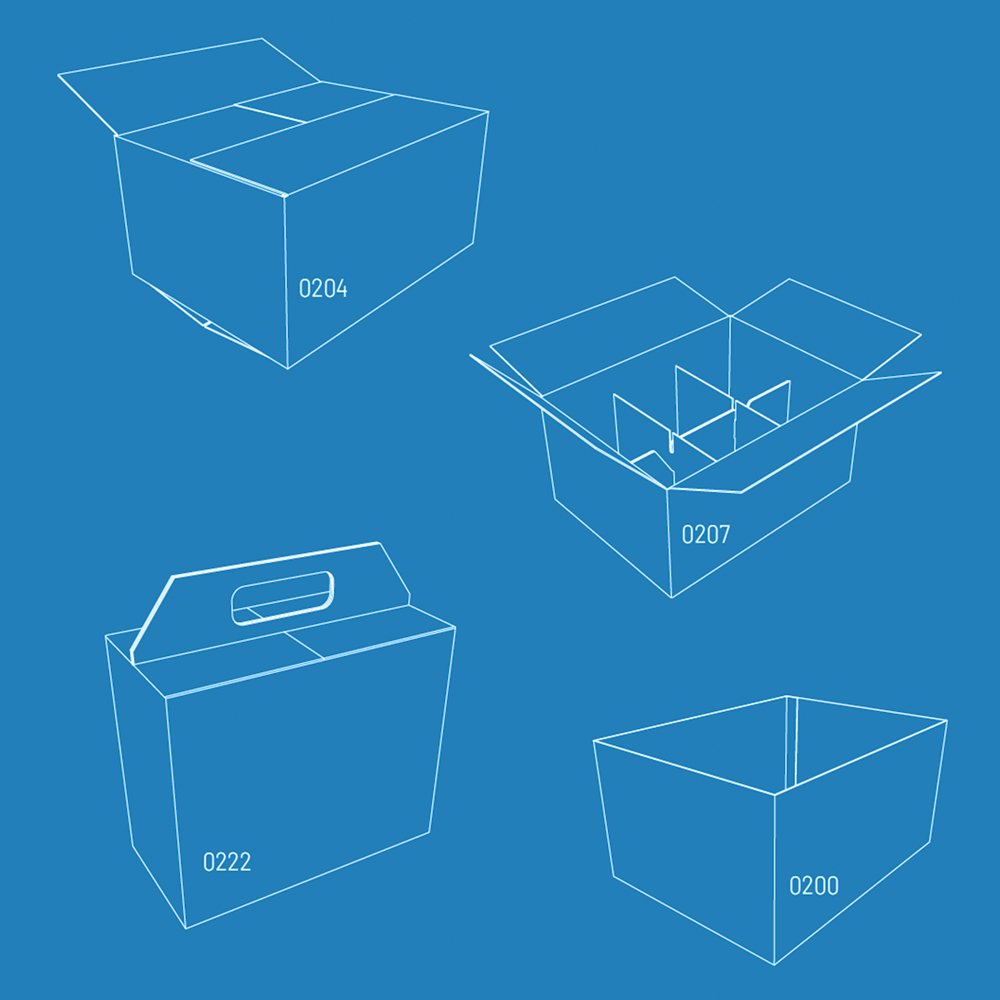

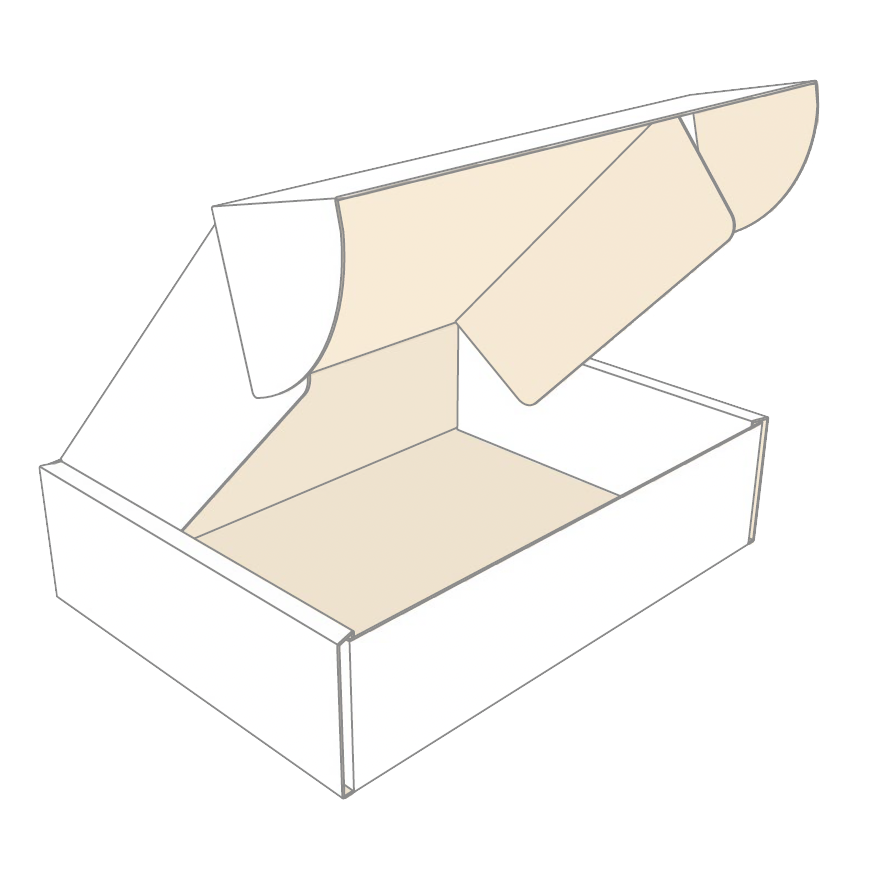

At Polydesign, we offer more than standard cardboard packaging. As an experienced manufacturer of corrugated boxes, we provide tailored packaging solutions that meet your business’s unique needs. Whether your goal is to reduce costs, minimize product damage in transit, or manage high packaging stock more efficiently, our broad range of services has you covered.

From initial concept through to final delivery, Polydesign takes pride in delivering bespoke solutions to businesses just like yours.

Contact Harji Kaur

Why Us for Your Packaging?

Many businesses have come to rely on Polydesign not only for high-quality corrugated boxes but also for our customer-focused services, which include stock management, delivery optimization, and custom packaging design.

- Partnership Approach: We work closely with your business to fully understand and meet your packaging requirements.

- Focus on Customer Service: Our team provides friendly, professional support at every level of the process.

- Cost Savings: We help reduce costs through efficient design, inventory management, and streamlined packing processes.

- Modern Production Facilities: Equipped with state-of-the-art manufacturing technology, we ensure quick production times and high-quality output.

- Proven Design Expertise: Our extensive experience in packaging design helps ensure your packaging performs effectively in every situation.

Die Cut Cardboard Inserts

Our new die-cutting machine offers precision and versatility, capable of handling a variety of materials. With a platen size of 1500x1050mm, we specialise in cutting card, corrugated, and paper products. However, we are always eager to expand our offerings—if you have a different material in mind, give us a call and we’ll gladly explore the possibility of adding it to our capabilities/services.

Digital Cutting Capabilities/services

Our Kongsberg flatbed digital cutting table offers precision cutting for short runs and prototypes with flexibility. The cutting area is 1680 x 3050mm and currently, we specialise in cutting card, corrugated, and paper products. However, we are always open to expanding our material options—if you have a specific material in mind, contact us, and we’ll be happy to explore the potential of adding it to our capabilities/services

FAQs About Corrugated Cardboard Boxes

Corrugated cardboard is made by sandwiching a fluted layer of material between two flat sheets, called liners. This creates a sturdy, crush-resistant structure that’s perfect for packaging. The fluted middle layer adds strength, making it ideal for protecting goods during shipping.

- Single Wall: Consists of one fluted layer between two liners. It’s suitable for lighter items and can generally handle weights up to 10kg.

- Double Wall: Two fluted layers provide extra strength, making it capable of holding up to 30kg. Ideal for heavier goods that need more protection.

- Triple Wall: Three layers of fluting for maximum strength, capable of handling large, heavy items. Great for palletising and shipping items up to 50kg, ensuring safe transport even under pressure.

- Kraft Paper: Made from virgin wood pulp, kraft paper is the strongest and most durable option. It is commonly used for the outer liners of corrugated cardboard, providing excellent protection and structural integrity.

- Test Paper: This is a recycled option often used for the inner liner of corrugated cardboard. While not as strong as kraft, it’s eco-friendly and cost-effective, making it a suitable choice for lightweight packaging applications.

- Fluting: The fluted layer, positioned between the liners, adds strength and cushioning to the corrugated cardboard. It is typically made from recycled paper, providing a balance between strength and weight. The fluting structure is essential for enhancing the compressive strength and shock absorption of the cardboard, making it ideal for protecting goods during transit.

- Other Paper Types: Depending on specific packaging needs, corrugated cardboard may also incorporate recycled or semi-chemical paper variants to optimise cost and performance.

Corrugated cardboard weight is measured in grams per square meter (gsm). This refers to the weight of one square meter of the material. Higher gsm numbers generally indicate a stronger material.

Double or triple wall boxes offer the best protection against crushing. These multi-layered boxes are designed to withstand stacking and rough handling during transit, making them the best choice for safeguarding your products. You can also combine these boxes with polystyrene endcaps or polystyrene packaging for enhanced protection, especially when shipping fragile or valuable items.

For fragile or delicate items, we recommend double or triple wall boxes for added protection. To further safeguard your products, use polystyrene packaging or polystyrene endcaps to cushion your items inside the box. These materials help absorb impacts and protect against shocks that the box alone may not handle.

Yes, we offer a range of standard box sizes suitable for most common packaging needs. However, if your products require custom sizes or shapes, we can also provide bespoke packaging solutions tailored to your specifications.

Our press platen size is 1500x1050mm, and our flatbed digital cutting area is 1680x3050mm. This allows us to create large, custom boxes to meet your packaging needs, especially for oversized or uniquely shaped items.

Corrugated cardboard is sometimes referred to as corrugated fibreboard, combined board, or corrugated board. It’s important to note that “cardboard” by itself doesn’t always mean corrugated—it could refer to thinner, less durable materials like paperboard.

While the natural brown finish is the most common, corrugated cardboard is available in other colours such as white. However, please note that we are unable to offer custom printing on our packaging at this time.