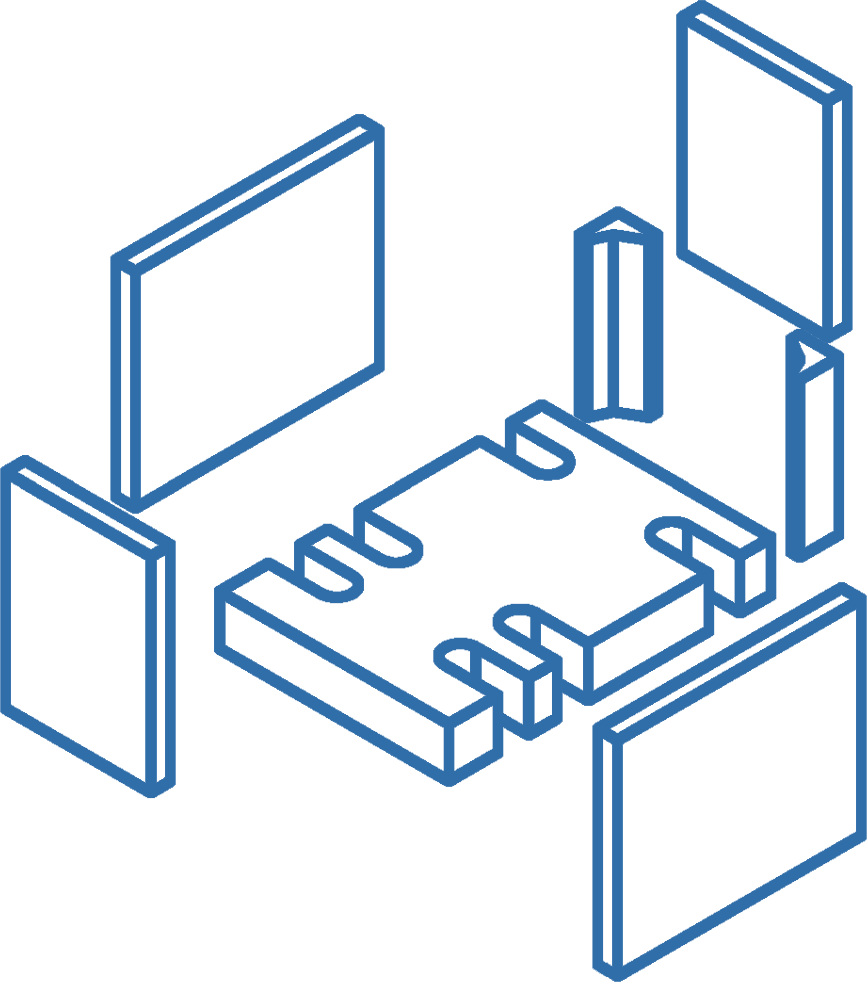

Custom Polystyrene Packaging

Polystyrene Packaging

At Polydesign, we specialise in the creation of custom polystyrene products designed to meet the unique needs of your business. Whether you’re looking for tailored packaging solutions, construction components, or durable protective materials, our expertise ensures your products stand out and are protected in transit.

With decades of experience and a commitment to innovation, we combine state-of-the-art manufacturing techniques with eco-friendly practices to deliver exceptional, high-quality solutions.

Contact Harji Kaur

Why Us for Polystyrene Packaging?

As a family-owned business, we pride ourselves on delivering innovative and sustainable solutions. Our team of experts works closely with you to ensure that your polystyrene products are tailored to your specific needs, providing the best possible protection for your goods or enhancing your construction projects.

- Custom Design Expertise: We provide bespoke polystyrene products tailored to your exact requirements.

- Sustainability Focus: Our products are made using eco-friendly materials and processes, contributing to your sustainability goals.

- Durable Protection: Our packaging solutions are designed to withstand the rigors of transit, ensuring your products arrive safely.

- Family-Owned Dedication: We’re committed to delivering exceptional customer service and building lasting relationships with our clients.

Our polystyrene packaging solutions cover a wide range of needs, including:

- Edge protectors, corners, wedges, channels, boxes, and mirror packs

- Sheets, pads, and spacers for general packaging purposes

- Packs and end caps for protecting TVs, PCs, and other electronic devices

- Display and construction

- Display packaging for giftware, luxury items, mugs, and glasses

- Test tube trays designed for the medical and educational sectors

FAQs – About Polystyrene Packaging

Yes, polystyrene is recyclable, although there is a widespread myth that it cannot be recycled. The key to recycling polystyrene is to have access to proper facilities, as it is not always accepted in standard curbside recycling programmes. However, with specialised recycling systems, polystyrene can be compacted and processed into materials that can be used for creating new products, such as insulation, plastic items, and even new packaging materials. The recycling process significantly reduces the environmental impact of polystyrene, diverting it from landfills and reintroducing it into the supply chain. Due to its lightweight and versatile properties, polystyrene recycling consumes less energy compared to other plastics, making it a more sustainable option when handled correctly. It’s vital that businesses and consumers help to support the development and utilisation of recycling infrastructure to ensure that polystyrene can be effectively reused rather than discarded.

Polystyrene comes in a range of densities, suited to different applications. Expanded Polystyrene (EPS) is the most common and comes in densities ranging from light packaging foam to higher-density types used in construction. Depending on the application, choosing the correct density is crucial for balancing weight, strength, and insulation properties.

Polystyrene is safe to use in normal conditions and does not emit harmful fumes during typical use. However, when polystyrene is burned or exposed to very high temperatures, it can release harmful chemicals, including styrene gas and other compounds. This is why it is crucial to avoid subjecting polystyrene to open flames or high heat. Under proper use conditions, polystyrene poses no danger to air quality or health.

Polystyrene has its environmental challenges, but it is far more sustainable than many realise. While it is not biodegradable and can persist in landfills for a long time, the fact that it is recyclable mitigates much of its environmental impact. When recycled properly, polystyrene can be repurposed into new products, which helps reduce the need for virgin materials. Additionally, polystyrene’s lightweight nature means it requires less fuel for transportation, reducing carbon emissions during transit. Its insulating properties, particularly in construction, also contribute to energy savings by reducing the need for heating and cooling in buildings. With proper recycling practices in place, polystyrene can play a part in sustainable development, especially when compared to non-recyclable or less energy-efficient alternatives.

No, you do not have to pay the plastic tax when purchasing our polystyrene products. We use a composition of 70% recycled and 30% virgin materials in our polystyrene, which qualifies us for exemption from the plastic tax. The plastic tax was introduced to incentivise the reduction of plastic waste and promote the use of recycled materials. By utilising a significant portion of recycled content in our products, we not only align with sustainable practices but also avoid the additional costs associated with the tax. This commitment to recycling helps lower our environmental footprint while providing cost-effective solutions for our customers.

Our standard lead time for most polystyrene orders is 5-7 working days. However, we understand that urgent needs may arise. For short notice or priority orders, we are flexible and can often expedite production to meet tighter deadlines. If you have an urgent request, we encourage you to contact us, and we will do our best to accommodate your timeframe.

No, we do not have a minimum order quantity (MOQ). Whether you require a small, one-off batch or a large production run, we can fulfil your needs. This flexibility is ideal for businesses of all sizes and allows you to order exactly what you need without unnecessary commitments to large volumes.

Polystyrene can be painted using water-based paints, such as acrylics or latex, without damaging the material. However, solvent-based paints and varnishes should be avoided as they can dissolve or degrade the polystyrene surface. If you need to decorate or colour polystyrene, we recommend sticking to water-based coatings for the best results.

While we do not specialise in food packaging, polystyrene is widely used for certain food containers and packaging applications. It is considered safe for food contact when produced under the right standards. However, it’s always important to verify the specific product’s compliance with food safety regulations.

Yes, polystyrene contributes significantly to energy efficiency. Its insulating properties help maintain consistent indoor temperatures, which can lower the need for heating and cooling in buildings. By reducing energy consumption, polystyrene can lower energy costs and decrease the carbon footprint of buildings where it is